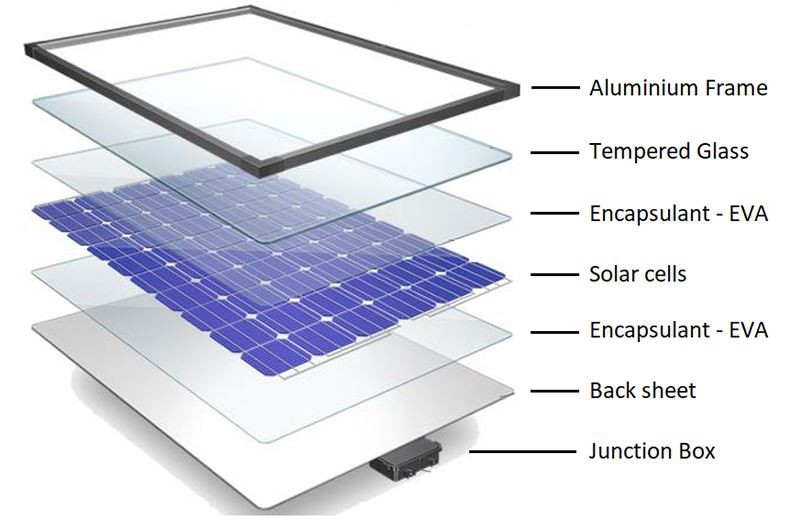

The core materials for assembling photovoltaic modules include tempered glass, EVA film, solar cells, backsheets, aluminum alloy frames and junction boxes. These materials work together to achieve functions such as photoelectric conversion, structural protection, and current transmission.

Solar PV module disassembly Schematic diagram

Solar panel frames, also known as aluminum extrusion frames, are key components of solar panels. These frames secure and seal key solar panel components, including the solar backsheet and cover glass. Strong yet lightweight, aluminum frames not only provide mechanical support for the solar cells but also enhance the solar panel's resistance to weather conditions and other external factors.

Aluminum frames strengthen the overall rigidity of solar panels, enabling them to withstand the weight of accumulated snow and other forces they may encounter during their lifespan.

Aluminum frame's inherent corrosion resistance makes it an essential material for protecting solar panels. It effectively shields solar modules from moisture, dust particles, rain, and other harmful elements. Aluminum solar panel frames effectively drain water and prevent debris from accumulating on the panels. The frames also help prevent moisture from penetrating the panels and damaging their electronic components.

Aluminum Frame

Solar Cell

A solar cell, also known as a photovoltaic cell, is a device that converts sunlight into electricity through the photovoltaic effect. This process involves certain materials generating an electric current when exposed to sunlight. Solar cells are a fundamental component of solar panels, which are widely used to harness solar energy for a variety of applications, including electricity generation.

Crystalline Silicon Solar Cells

Crystalline silicon is the most commonly used material for commercial solar cells. It combines low cost, high efficiency up to 26%-27%, long-term stability and durability, and solid industrial technical knowledge. Silicon has an energy band gap of 1.12 eV, which is a good match to the solar spectrum.

Solar cells made from silicon are the most popular choice for today's solar panels. Crystalline silicon can be categorized into different types, namely Monocrystalline Silicon and Polycrystalline Silicon.

Monocrystalline Silicon – This is a highly efficient type of solar cell used in premium solar panels. They generally offer more power output than rival products but are far more expensive. Solar panels using monocrystalline silicon cells feature a distinctive pattern of small white diamonds. This is due to how the wafers are cut.

Polycrystalline Silicon – Also known as 'multicrystalline silicon', this type of solar photovoltaic cell is the most common. Due to its popularity and a more efficient manufacturing process (involving molten silicon), solar panels using cells of this type are often the cheapest to buy.

Thin Film Solar Cells

Thin-film solar cells, also known as thin-film photovoltaic cells because they consist of multiple layers of thin films of photovoltaic material that are much thinner than typical P-N junction solar cells. These cells are manufactured using materials such as amorphous silicon, cadmium telluride, and copper indium gallium selenide. The operating principles of thin-film solar cells are virtually identical to those of conventional silicon wafer-based cells. However, the flexible arrangement of the multiple layers of material in thin-film cells differs from that of silicon cells.

Solar panels using thin film solar cells are less common than crystalline silicon alternatives. Although they tend to be cheaper, their performance isn't as good as c-Si technology. A benefit of thin film cells is that they are flexible and therefore slightly more durable.

The most popular materials in thin film solar cells are as follows:

Amorphous Silicon – This is a popular material used widely on thin film solar cells. It uses around 1% of the silicon that a traditional crystalline silicon cell contains, making it considerably cheaper.

Cadmium Telluride – Cadmium solar cells are the only thin film product to have rivaled the performance of monocrystalline silicon cells. The drawback to this material is that it is highly toxic, causing concern regarding the disposal of old cadmium cells.

Copper Indium Gallium Selenide (CIGS) – This is the third mainstream thin film solar cell technology. When we compare this to crystalline silicon, CIGS cells can be anywhere between 80 and 160 times thinner.

Tempered glass

Photovoltaic glass refers to the glass used on solar photovoltaic modules, which has important values such as protecting batteries and transmitting light.

Protection from damage - Tempered solar panel glass serves as a protective layer for solar panels, preventing environmental factors like vapors, water, and dirt from damaging the photovoltaic cells. Tempered solar panel glass also provides high strength, excellent transmissivity, and low reflection.

Durability and safety - Tempered glass offers up to four times more strength than standard glass. This strength is critical as the solar panel's front sheet requires lasting protection against the elements. Thanks to the thermal and chemical processes that produce tempered glass, it is also known as toughened or safety glass. Tempered glass is safer to use because it shatters into many smaller pieces when broken, reducing the probability of accidental injury.

EVA film

Ethylene vinyl acetate (EVA) is a thermoplastic polymer that possesses good radiation transmission and low degradability to sunlight. It is used in the Photo-Voltaic(PV) industry as an encapsulation material for crystalline silicon solar cells in the manufacture of PV modules. Solar EVA films protect solar panels for long time with little loss in performance.

Solar EVA sheet is a milky white, rubbery substance. When heated, it transforms into a transparent protective film that seals and insulates the solar cells. Using a laminator, the cells are pressed between the EVA sheets in a vacuum environment, where temperatures reach up to 150°C.

It is important to note that EVA film is not UV-resistant, so a front glass is required for UV shielding. After lamination, the ethylene-vinyl acetate sheet plays a vital role in preventing moisture and dust from entering the solar panel. The EVA sheet helps the cells float between the glass and backsheet. This structure mitigates shock and vibration, protecting the solar cells and their circuitry from physical damage. It also prevents oxygen and other gases from oxidizing the cells during normal power generation, thereby extending the solar cell's lifespan.

Backsheet

The back of a photovoltaic module uses a backsheet film. The backsheet is a multilayer laminate made from various polymer materials and inorganic modifiers. This multilayer structure allows the backsheet's optical, thermomechanical, electrical, and barrier properties to be tailored to the specific requirements of the photovoltaic module. They play a vital role in protecting them from harsh, changing environmental conditions throughout their lifetime.

Not all backsheets are created equal. To protect solar panels for over 25 years, they must achieve an optimal balance of three key properties: weather resistance, mechanical strength, and adhesion. These properties must remain stable throughout the module's lifetime.

Backsheet-related failures can lead to catastrophic failure of solar panels, severe power degradation, and serious safety hazards. The impact can be severe, ranging from significant brand and reputation damage to personal injury.

Backsheets found in PV-modules can be classified into three groups. The backsheets of the first class are composed of a single major polymer component, polyamide (PA), while the BSs of the second and third classes are multi-component and multi-layer backsheets. The multi-component backsheets are comprised of a polyethylene terephtalate (PET) core layer. The second class has a symmetric layer structure, which means that there is a fluorinated polymer at the inner layer as well as on the airside layer. In contrast, the third backsheet class has an asymmetric structure: a PET core layer, a single fluorinated coating (FC) layer at the airsides, and inner layers of polyolefines, such as polyethylene (PE), polypropylene (PP).

Junction box

The junction box is attached to the back of the module with adhesive. Its primary function is to output the electricity generated by the solar modules via cables.

The junction box acts as a connector, bridging the gap between the solar modules and control equipment such as inverters. Inside the junction box, the current generated by the solar modules is channeled through terminals and connectors and then directed to the consumer. The mechanical strength and electrical stability of the electrical terminals in the junction box are critical to the safe, reliable, and long-term operation of photovoltaic (PV) modules. This feature is expected to extend the 25-year warranty period of typical PV products.

The junction box's protective functions include three aspects: first, bypass diodes prevent hot spot effects, protecting the cells and modules; second, a unique sealing design provides waterproofing and fireproofing; and third, a unique heat dissipation design reduces the operating temperature of the junction box and the bypass diodes, thereby reducing power loss caused by leakage current in the modules.

Weather resistance refers to the ability of materials such as coatings, plastics, and rubber products to withstand the rigors of outdoor use, such as extensive damage caused by sunlight, heat, cold, wind, rain, and bacteria. This resistance is called weather resistance.