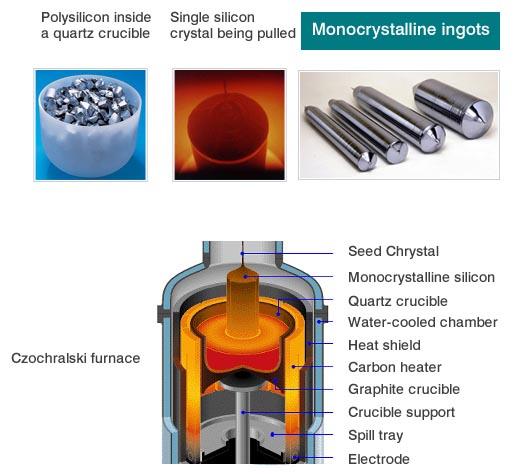

This specification defines N-Type Monocrystalline Silicon Wafers (Size M10) for advanced solar cells. Produced via the Czochralski method with Phosphorus doping, the wafers feature low oxygen concentration (up to 8E17 at/cm³), low carbon concentration (up to 5E16 at/cm³), etch pit density up to 500 cm⁻², and precise surface orientation within 3 degrees of <100>.

Key electrical properties include a resistivity range of 1.0 to 7.0 Ω.cm and high minority carrier lifetime (minimum 1000 μs).

The wafers have an optimized pseudo-square geometry with side length 182 mm (tolerance 0.25 mm), diameter 247 mm (tolerance 0.25 mm), and adjacent sides at 90 degrees (tolerance 0.2 degrees). Available in thicknesses from 150 to 180 μm (with tolerances), they ensure minimal thickness variation (TTV maximum 27 μm). Surface quality is strictly controlled ("as cut and cleaned"), prohibiting contamination and micro-cracks, with limits on saw marks (maximum 15 μm), bow, and warp (maximum 40 μm each). This large format supports the industry's shift towards optimized light capture.

1. Material properties

|

Property |

Specification |

Inspection Method |

|

Growth method |

CZ |

|

|

Crystallinity |

Monocrystalline |

Preferential Etch Techniques(ASTM F47-88) |

|

Conductivity type |

N-type |

Napson EC-80TPN |

|

Dopant |

Phosphorus |

- |

|

Oxygen concentration[Oi] |

≦8E+17 at/cm3 |

FTIR (ASTM F121-83) |

|

Carbon concentration[Cs] |

≦5E+16 at/cm3 |

FTIR (ASTM F123-91) |

|

Etch pit density(dislocation density) |

≦500 cm-2 |

Preferential Etch Techniques(ASTM F47-88) |

|

Surface orientation |

<100>±3° |

X-ray Diffraction Method (ASTM F26-1987) |

|

Orientation of pseudo square sides |

<010>,<001>±3° |

X-ray Diffraction Method (ASTM F26-1987) |

2.Electrical properties

|

Property |

Specification |

Inspection Method |

|

Resistivity |

1.0-7.0 Ω.cm

|

Wafer inspection system |

|

MCLT (minority carrier lifetime) |

≧1000 µ |

Sinton BCT-400

Transient

(with injection level: 5E14 cm-3)

|

3.Geometry

|

Property |

Specification |

Inspection Method |

|

Geometry |

pseudo square |

|

|

Bevel edge shape

|

round | |

|

Wafer Side length |

182±0.25 mm

|

wafer inspection system |

|

Wafer Diameter |

φ247±0.25 mm |

wafer inspection system |

|

Angle between adjacent sides |

90° ± 0.2° |

wafer inspection system |

|

Thickness |

180 ﹢ 20/﹣10 µm

175﹢ 20/﹣10 µm

170﹢ 20/﹣10 µm

165﹢ 20/﹣10 µm

160﹢ 20/﹣10 µm

150﹢ 10/﹣10 µm

|

wafer inspection system |

|

TTV (Total thickness variation) |

≤ 27 µm |

wafer inspection system |

4.Surface properties

|

Property |

Specification |

Inspection Method |

|

Cutting method |

DW |

-- |

|

Surface quality |

as cut and cleaned, no visible contamination, (oil or grease, finger prints, soap stains, slurry stains, epoxy/glue stains are not allowed) |

wafer inspection system |

|

Saw marks / steps |

≤ 15µm |

wafer inspection system |

|

Bow |

≤ 40 µm |

wafer inspection system |

|

Warp |

≤ 40 µm |

wafer inspection system |

|

Chip |

depth ≤0.3mm and length ≤ 0.5mm Max 2/pcs; no V-chip |

Naked eyes or wafer inspection system |

|

Micro cracks / holes |

Not allowed |

wafer inspection system |

Hot Tags: n-type m10 monocrystalline silicon wafer specification, China, suppliers, manufacturers, factory, made in China